In modern manufacturing facilities, not only power but also directional control and flexibility are of critical importance during transport processes. Multi-directional transfer carts ensure safe and efficient movement even in the most complex factory layouts, thanks to their trackless structure and advanced wheel control system.

These systems are developed specifically for:

- Narrow aisles,

- Busy production lines,

- Variable transport routes.

With their 360° rotation capability, they offer seamless access to every corner of the production area.

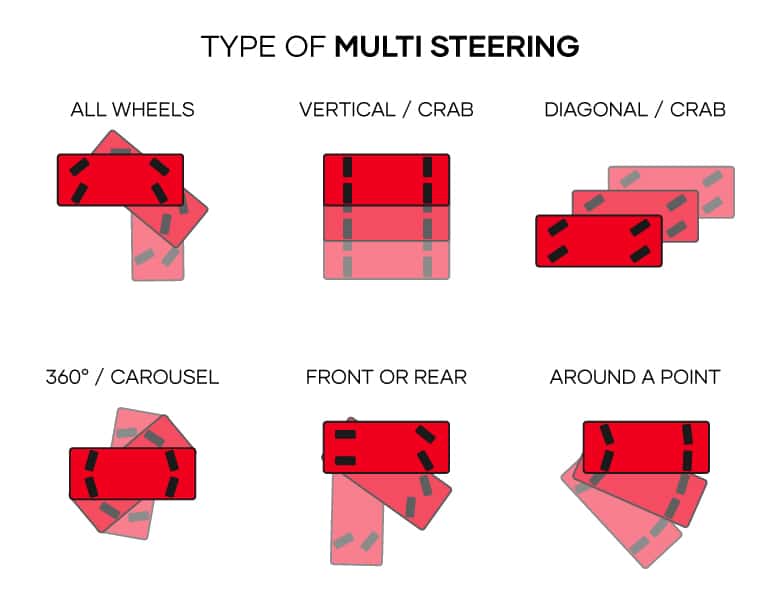

Multi-wheel steering transfer carts execute turning movements not only with the front wheels but through the synchronized control of all wheels. This enables the transfer cart to perform the following specialized maneuvers:

- Center Rotation (360°): The ability to rotate around its own axis provides superior maneuverability in confined spaces.

- Crab Move: Moving laterally (sideways) to transport loads across parallel lines significantly reduces positioning time.

- Circular or Diagonal Maneuvers: Offers high-level control on routes requiring precise guidance.

- Turning in Tight Spaces: Executes turning maneuvers in extremely narrow areas using variable wheel angles.

This advanced mobility provides significantly greater operational flexibility compared to conventional steering systems.

Technical Features

- Drive System: All-wheel steering

- Steering Angle: Free steering between 0°–90°

- Power Source: Battery (Type determined based on requirements)

- Load Capacity: 10 t – 500 t (Customizable per project)

- Speed Range: 10 – 20 m/min (Customizable)

- Floor Suitability: Concrete, epoxy, or flat factory floors

- Control: Remote control, operator panel, or fully automated control system

- Safety Equipment: Laser scanners, strobe lights, audible warning systems, emergency stop buttons

Note: Each model is custom-designed and tested according to the specific needs of the client’s facility.